The abrasive fiber disc is an abrasive disc made of a stiff fiber backing material and abrasive grains, designed for use in various grinding and finishing applications. Here are some of the different types of abrasive fiber discs:

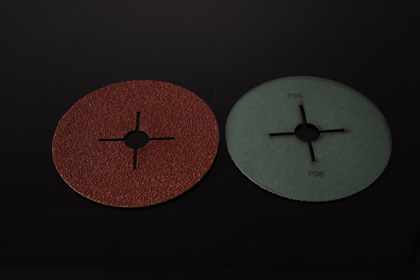

RMC Aluminum oxide fiber disc use strong heavy-duty vulcanized fiber backing, full resin bonded.

Read More

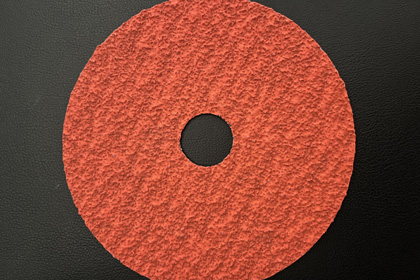

RMC Ceramic fiber disc is strong and has durable, long sanding life, high sanding performance.

Read More

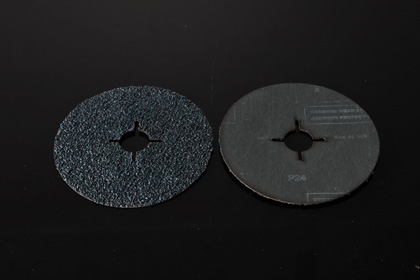

RMC zirconium oxide fiber disc suitable for grinding and polishing metal, stainless steel and other hard sanding materials.

Read More The abrasive fiber disc is meant to remove a great deal of metal without the vibration, noise, and unforgiving nature of grinding wheels. However, there are high and low limits of downforce pressure to get the maximum benefits of fiber abrasive disc. There is no need to apply extreme forces to remove metal.

Specializing in abrasives wholesale, our abrasive fiber disc is suitable for grinding and polishing metal, non-metallic, rubber, leather, plastics, stone, glass and other materials.

Leading Fibre Disc Manufacturer in China: RMC is a leading abrasives manufacturing company in China, known for producing high-quality abrasive fiber discs at competitive prices. With state-of-the-art manufacturing facilities and a team of experienced professionals, RMC is committed to providing customers with the best fiber abrasive disc in the market.

Wide Range of High-Quality Fiber Discs: At RMC, we offer a wide range of fiber discs in different sizes, grits, and materials to meet various grinding and finishing needs. Our fiber abrasive disc is made using high-quality abrasive material and bonding agent, ensuring maximum durability and performance.

Commitment to Excellent Service and Competitive Prices: As one of the most professional fibre disc manufacturers in China, we are dedicated to providing our customers with excellent service, fast delivery times, and competitive prices. We understand that price is an important factor for our customers, and we strive to keep our fibre grinding disc price low without compromising on quality.

Versatile Applications for Various Industries: Whether you need fiber discs for metalworking, woodworking, or other applications, RMC has you covered. Contact us today to learn more about our fibre grinding disc products and pricing.

Here are some factors to consider when choosing a fiber grinding disc:

Different types of resin sanding disc are suitable for different materials. For example, ceramic and zirconia discs are best for grinding and finishing hard metals, while aluminum oxide discs are better for softer metals and non-metallic materials.

Consider the task you will be performing, whether it is stock removal, grinding, or finishing. Different types of fiber grinding discs are designed for specific applications and can vary in terms of aggressiveness, durability, and finish quality.

The grit size of the disc determines its aggressiveness and finish quality. The higher the grit size, the finer the finish. Consider the level of finish required and the amount of material to be removed when selecting the grit size.

The size of the disc should match the size of the grinder or sander being used. Larger discs are better suited for heavy-duty applications, while smaller discs are ideal for precision work.

Fibre sanding disc comes in different types, such as flap discs, quick-change discs, and standard discs. Consider the type of grinder or sander being used and choose a compatible disc type.

Fiber grinding discs are designed to be used at specific speeds and pressures. Ensure that the disc you choose is compatible with the grinder or sander being used and that the speed and pressure settings are within the recommended range.

We are passionate about professional abrasive solutions for industry and trades.

No. 61, Qinfen Road, Xinbei District, Changzhou, Jiangsu Province, China.