The three elements of grinding? Iron, stainless steel, copper, aluminum alloy, zinc alloy, magnesium alloy, titanium alloy and other metal materials surface treatment, chamfering, deburring, polishing.

Sanding Belt Manufacturers makes a simple analysis of the three elements:

1. In the surface treatment of the machine, the commonly used machines include vibrating type finishing machine, drum type finishing machine, centrifugal grinding machine, eddy current type finishing machine, among which vibration type finishing machine and drum type finishing machine are the most used. wide.

The dynamic finishing machine is easy to operate and is used for the processing of various parts in small, medium and large batches; the drum finishing machine is an economical grinding and polishing machine. The parts and the grinding media are horizontal in a closed drum during operation. Rotation, slower speed, often used for small size, thinner parts, especially those parts with larger planes, it is easy to overlap with vibration type finishing machine processing, more suitable for barrel type finishing machine; centrifugal grinding machine In fact, it is a high-speed drum finishing machine. It is generally driven by a large plate to drive four centrifugal polishing barrels (there are also two for small machines) to rotate at high speed, with high friction and good polishing effect. It is often used in vibrating finishing machines and drums. Small parts that are not easy to be processed by the finishing machine; the eddy current machine is also a high-speed polishing machine, which forms a strong overcurrent friction movement through the rotation of the chassis, which is used for the sharpening, deburring and polishing of small parts.

2. Workpiece Parts with different materials, parts with different specifications, and parts with different requirements also require different machines and grinding media.

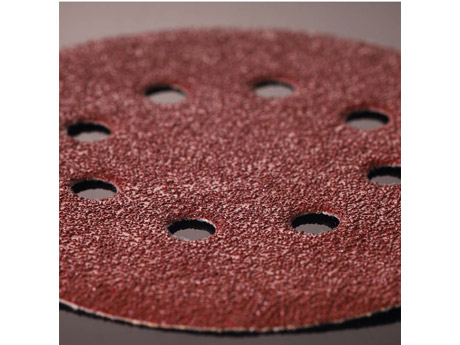

3. Grinding media Grinding media include grinding stones, polishing stones, abrasives, gloss agents and other grinding and polishing materials. Each material has its own application range. For example, plastic grinding stones are used for softer materials, such as aluminum, zinc, Copper, plastics, etc.; ceramic grinding stones are used for hard materials, such as iron, stainless steel, white iron, steel, etc.; for parts made of iron, iron gloss agent is required, and parts made of copper are required for polishing. To copper gloss agent, hand tool cutting agent is used for all kinds of wrenches, sockets, nozzles to remove black film and scale. If used for other parts, it may corrode the parts. In general, only a full understanding of grinding three The performance and characteristics of the elements can be effectively matched to achieve a multiplier effect.

Our company also has Velcro Disc on sale, welcome to contact us.