When it comes to surface preparation and finishing, the right tools can make all the difference in achieving a smooth, clean, and polished result. The shaft flap wheel from RMC Abrasives provides an efficient solution for a variety of applications, from deburring and rust removal to polishing and surface smoothing. This versatile abrasive tool is designed to deliver exceptional performance on metals, wood, and other materials, ensuring high-quality finishes in a fraction of the time compared to traditional methods.

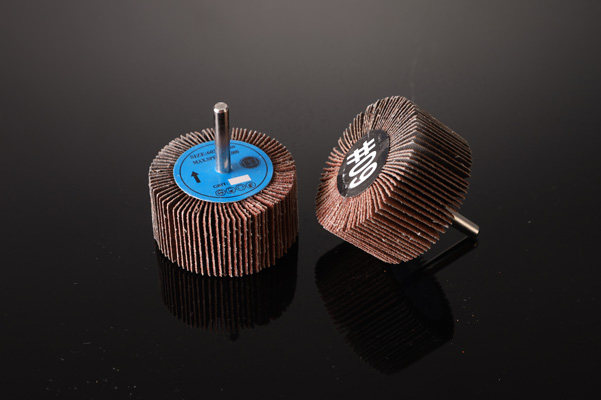

A shaft flap wheel combines the flexibility of a flapper wheel with the convenience of a pre-mounted shaft, allowing users to easily attach it to a power tool or rotary tool. This design enables precise control and flexibility, making it ideal for use on a wide range of surfaces and materials. Whether you're working on metal, wood, plastic, or even composite materials, the shaft flap wheel adapts to the contours and intricacies of the material, ensuring a consistent finish across both flat and curved surfaces.

One of the key advantages of this tool is its ability to provide both aggressive material removal and fine finishing in a single operation. The layered construction of the flap wheel, combined with its attachment to a shaft, allows for effective sanding, deburring, and polishing in a single motion, making it a time-saving choice for both professionals and DIY enthusiasts alike.

Surface preparation is crucial for ensuring that coatings, paints, or adhesives bond properly and evenly to the material surface. A shaft flap wheel is an essential tool for preparing metal, wood, and other surfaces by removing rust, oxidation, burrs, and old coatings. This is particularly beneficial in applications like welding, automotive repairs, or metalworking, where smooth, clean surfaces are needed before painting or finishing.

The construction of the shaft flap wheel allows it to remove unwanted material efficiently without damaging the underlying surface. The abrasive flaps are designed to wear down gradually as they are used, providing consistent sanding pressure and maintaining the integrity of the material. Whether you're preparing metal for welding or smoothing rough wooden surfaces, this tool ensures that the surface is perfectly prepped for the next step in the process.

Deburring and polishing are two critical steps in achieving a professional-grade finish. After processes like cutting, grinding, or welding, sharp edges and rough spots are common and can interfere with the overall quality of the finished product. The shaft flap wheel excels in these applications by providing a gentle yet effective solution for deburring and polishing, ensuring smooth and uniform surfaces.

For metalworking tasks, the shaft flap wheel removes burrs and sharp edges without causing excessive material removal. This is particularly important in industries like automotive manufacturing and machining, where precision is key. The tool's ability to polish surfaces to a high shine is another valuable feature, especially for finishing projects that require a mirror-like finish or smooth surface, such as metal polishing or furniture refinishing.

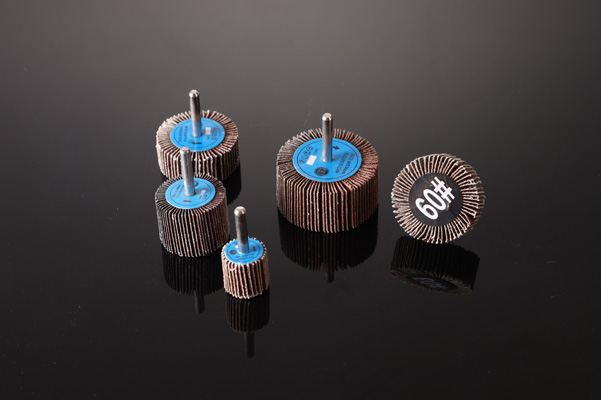

Selecting the right shaft flap wheel for your project depends on the material you're working with and the type of finish you require. Flap wheels are available in a range of grit sizes, from coarse to fine, allowing users to choose the right level of abrasiveness for their tasks. Coarser grits are ideal for aggressive material removal, while finer grits are better suited for polishing and finishing work.

For example, a shaft flap wheel with a coarse grit is perfect for deburring and removing heavy rust or old paint, while a medium or fine grit wheel is ideal for polishing metal or wood surfaces. The right choice of grit ensures that you achieve the desired finish without unnecessary material loss or damage to the workpiece.

In industries like automotive, metalworking, and woodworking, the efficiency and precision of surface finishing tools like the shaft flap wheel are critical. The design of this tool allows for fast, precise, and consistent results, reducing the time spent on manual sanding or polishing. Its ability to quickly smooth rough surfaces or polish to a high finish makes it a must-have for professionals seeking to enhance productivity without sacrificing quality.

Moreover, the shaft flap wheel’s ability to work on various materials without needing frequent changes in tooling ensures that it remains a versatile and time-saving solution. Whether you're working on a delicate metal project or a rough wooden surface, this tool adapts to your needs, providing a smooth and professional finish every time.