Surface finishing is an essential step in many industrial and manufacturing processes, where the quality and consistency of the result are paramount. The right abrasive material can make all the difference when preparing surfaces for painting, coating, or polishing. Abrasive film has become one of the most trusted tools in this space, offering precision and control over the finishing process. From metalworking to woodworking, abrasive films provide an effective solution for achieving smooth, flawless results. This article will explore how abrasive film enhances surface finishing by offering superior precision, durability, and versatility.

Abrasive film stands out because of its ability to provide consistent, uniform results across various materials. Unlike traditional sandpaper, which can lose its abrasive qualities quickly and become uneven, abrasive films are designed to maintain their effectiveness throughout the sanding process. This consistency is crucial when working on delicate or high-precision projects, where an even finish is necessary to achieve professional results.

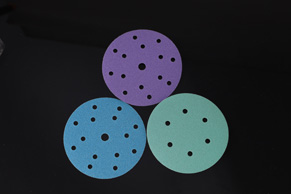

The film itself is made from a durable, flexible material that can conform to the surface shape. This flexibility makes it perfect for sanding and polishing complex or curved surfaces, which are often challenging with rigid abrasives. Additionally, abrasive films are available in a range of grit sizes, allowing users to choose the perfect level of abrasiveness for their specific task. Whether you are removing material quickly or achieving a fine finish, abrasive films can meet a wide variety of surface finishing needs.

The ability to maintain consistency is one of the primary reasons abrasive film is preferred in many industries. In applications that require high-quality finishes, such as automotive refinishing, metalworking, or woodworking, having an abrasive material that can consistently produce smooth surfaces is vital. Whether you are smoothing rough metal edges, polishing wooden surfaces, or preparing a substrate for painting, abrasive films offer the consistency needed to meet professional standards.

Unlike traditional sandpaper, which can develop uneven spots and become less effective over time, abrasive film maintains an even sanding profile throughout its use. This is due to the nature of its construction, which allows for uniform grit distribution. The result is a smooth, consistent finish that enhances the overall aesthetic and functionality of the product being worked on.

When performing high-precision sanding, it is essential to use a material that can stand up to the rigors of the task without breaking down prematurely. Abrasive film excels in this regard, offering extended durability compared to other types of abrasives like traditional sandpaper or cloth-backed sanding discs. The film's structure ensures that the abrasive material remains intact and effective, even after repeated use.

This durability is especially beneficial in industrial settings where sanding tools are put through heavy use. For tasks that require a consistent finish across multiple surfaces or long durations, abrasive film ensures that workers can continue their sanding tasks without needing frequent replacements. This makes it an excellent choice for both small-scale and large-scale operations that require long-lasting, reliable abrasives.

Abrasive film is versatile enough to be used across a wide range of materials, from metals and plastics to wood and composites. This makes it suitable for a variety of applications, from rough sanding to fine polishing. Whether you're working on a delicate wooden surface or preparing metal for welding or coating, abrasive films offer the necessary flexibility and precision to get the job done right.

For example, in metalworking, abrasive film is ideal for preparing metal surfaces for painting or coating by ensuring a smooth, even texture. In woodworking, it helps achieve a fine finish without causing scratches or damage to the surface. Whether you're tackling a large project or a small one, abrasive films can be adapted to meet the specific demands of the material you're working with, making them an indispensable tool for a wide variety of industries.

The power of precision that abrasive film brings to surface finishing cannot be overstated. Whether you're working on automotive repairs, metalworking, or fine woodworking, abrasive films provide the consistency, durability, and flexibility required for high-quality results. Their ability to conform to surfaces, maintain an even finish, and withstand prolonged use makes them an excellent choice for professionals in various industries. By incorporating abrasive film into your sanding and polishing processes, you can ensure that your projects meet the highest standards of surface quality, efficiency, and precision.